In 2015, Nestlé Professional started looking for an automated solution for the installation and maintenance of its business coffee machines. Visiting its dealers, the company was introduced to the service management software by Relyon, after which Nestlé became quickly convinced of its many benefits. Today, Nestlé’s enthusiasm for Relyon has only increased: the service process has become much more efficient and the management information is invaluable.

Nestlé is one of the big names in the food industry. The Swiss company is the largest in the world when it comes to nutrition, coffee and water. Coffee in particular deserves an honourable mention, as Nescafé coffee is after Coca-Cola the most widely consumed non-alcoholic beverage in the world: 7,000 cups per second across the globe. The Netherlands takes up its fair share of that number, as Nescafé isn’t just available in supermarkets, but also through the many business and commercial coffee machines run by Nestlé Professional and its dealers. The Nescafé machines are everywhere, from universities to hospitals, says René Akerboom, the Technical Support Manager responsible for the technical management of the coffee machines.

I have rarely seen a system that is this easy to use.

A lot of manual work

Akerboom has been working for Nestlé Professional since the nineties and soon focused on what became known internally as “the holy trinity”: coffee, technology and service. “To provide the perfect coffee experience, all three of these must be top of the bill”, Akerboom explains. “We already had the best coffee and the best machines, now we had to deliver the best service.” Starting in 1994, Nestlé Professional has been operating with its own service department in addition to a network of dealers. It is this department that Akerboom wanted to bring to the next level. The initial problem was that Nestlé is mainly a sales company. “We had no systems available for service; the ICT within Nestlé is focused on marketing and sales.”

This meant that until recently, servicing mostly involved manual work, with a physical planning board and an outdated card catalogue. “The planning was a lot of work”, admits Akerboom, “and we lacked overview. In case of sudden changes, things tended to go wrong. When clients asked for reports, it sometimes took me three days of work to get them. It also took a lot of calculating to determine what the appropriate price for a maintenance contract was”.

User-friendly system

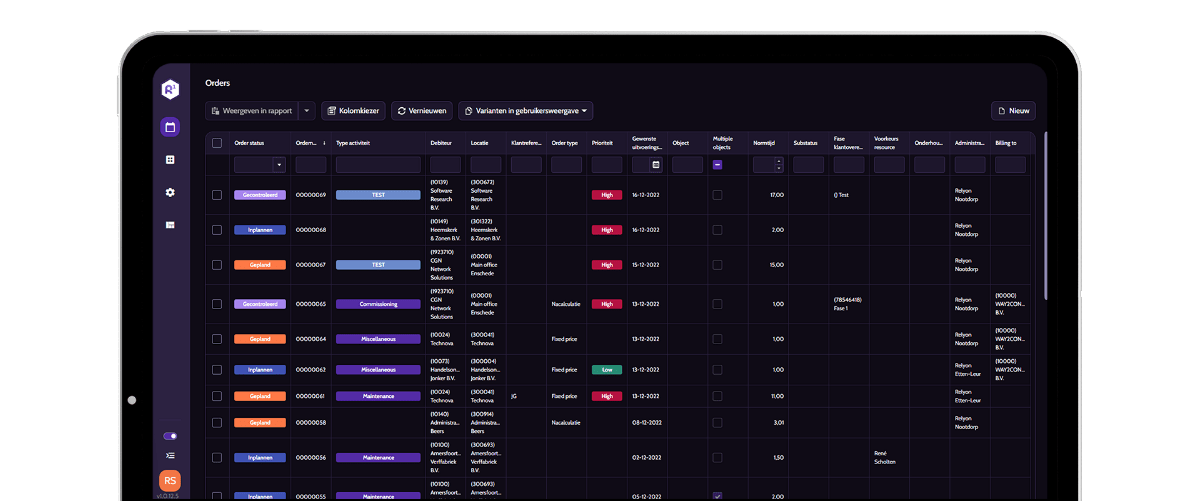

The first encounter with the Relyon software came in 2014, through the Nestlé Professional dealers. “These are technical service organisations and thus more likely to purchase software that fits their primary process”, says Akerboom. “Some were already working with Relyon and it seemed promising. We could ask them: what exactly can you do with it? Is it worth the investment? Of course we also looked at alternatives, but honestly, there weren’t many. Relyon made such an impression that the choice was simple. I’ve rarely seen a system that is this easy to use. And everything is done in Relyon, from timekeeping to parts usage.”

Nestlé began deploying the system the way it was used by several dealers, already fully designed for the maintenance of coffee machines, including visit registration, travel times and parts administration. Relyon has properly managed the implementation process, says Akerboom. “They responded quickly to questions and were with us at every step. And because the software is developed by Relyon itself, they were able to explain to me in detail what the system could and could not do.”

Foreign affiliates of Nestlé now visit us to see how we do things over here.

Identifying the problem

One of the changes that Akerboom wanted to see made to the system, was the ability to work with fault codes. “I wanted to dive deeper into the reasons why clients need to be visited. Because of a malfunction, obviously, but what is a malfunction? Service engineers had the possibility to enter the exact cause into a text field, but every engineer has his own way of describing things. That is hard to analyse. Relyon then created an addition in which engineers can enter fault codes that we developed ourselves.”

The extra functionality now enables Nestlé to figure out the actual costs per machine. “When we started with Relyon in May 2016, that was the main objective of Nestlé: gain insight into the behaviour of each type of machine and the costs related to it. Thanks to the fault codes, we know the weaknesses of some of the machines, which means we can put suppliers under pressure. And make no mistake, they appreciate it too! They crave information to improve their products.”

No more paperwork

By using the tablets, the service engineers now do their job with a great deal of satisfaction. They open the system in the morning and immediately see all the tasks for the coming period: from installation and maintenance to breakdowns and dealer support. Once they started, their initial concerns melted away completely, says Akerboom. “Some technicians had the idea that we wanted to keep an eye on them. And it’s true, thanks to Relyon we gain insight into how technicians do their work. But doesn’t everyone want to do a good job? Moreover, they can work as they always did, but there is no more paperwork involved. They are very happy with that, and they wouldn’t want it any other way.”

One of the things Nestlé refused to change was the self scheduling of maintenance visits. Akerboom: “We don’t plan maintenance visits centrally. Taking away our service engineers’ ability to schedule their own visits wasn’t something we wanted to do; they know best what part of the day their clients prefer. So through Relyon we now provide a monthly list with maintenance visits that have to be made. The engineers can go ahead and make their own timetable. Relyon delivered a nice report for that.”

Insight and time savings

Nestlé also discovered the differences in approach between the service engineers. “We see for example that one engineer likes to play it safe and replace a part more often than another engineer. Mind you, that doesn’t have to be a bad thing. If you can save a maintenance job with 50 euros worth of extra parts, that’s the smart thing to do. With the insight provided with Relyon, we can now see exactly what the most advantageous approach is.” In addition, the back office has gained a lot of time, Akerboom says. “In the morning, the staff doesn’t need to call all the service engineers anymore to give them the worklists. That time is now used to take care of the supply of parts. That used to be done manually, with engineers having to pick up new parts every 14 days. Now these are automatically supplemented every week.”

When Nestlé Professional chose Relyon, service management software was completely new to Nestlé. “I have had to do some serious talking to convince people”, concludes Akerboom, reflecting. “But now foreign affiliates of Nestlé visit us to see how we do things over here. There is no greater compliment imaginable. To ourselves, but also to Relyon.”