Ever since Bandenservice Zuid-West started working with AFAS and Relyon software, things have calmed down within the company. Due to the high degree of automation, the tyre specialist for agriculture, transport and industry can now switch more quickly, while the processes still run organised. Internally, the company saves a lot of time; the customers are more satisfied than ever.

Bandenservice Zuid-West was founded in 1987 and specialises in tyres for vehicles in the agricultural, transport and industrial sectors. The largest tyres the Klaaswaal based company supplies, are up to two metres high. When changing tyres, often specialised equipment is required. For that purpose, three service trucks are available across the country. The trucks also deliver tyres, in case the customer can manage to change them himself. The company has been collaborating with AFAS after the founder’s son took over the business. He started working with AFAS right away. Bandenservice Zuid-West now uses the entire package from bookkeeping to personnel administration, say Piet van der Veer and Marius Dorst, responsible for planning at the tyre specialist. The company also has a web shop: trekkerbandenmarkt.nl, which is supported by AFAS as well.

It has taken away a lot of stress, for ourselves as well as for the customers. For the customer it is clear now: a deal is a deal. That’s a promise we can keep every time.

Five specific questions

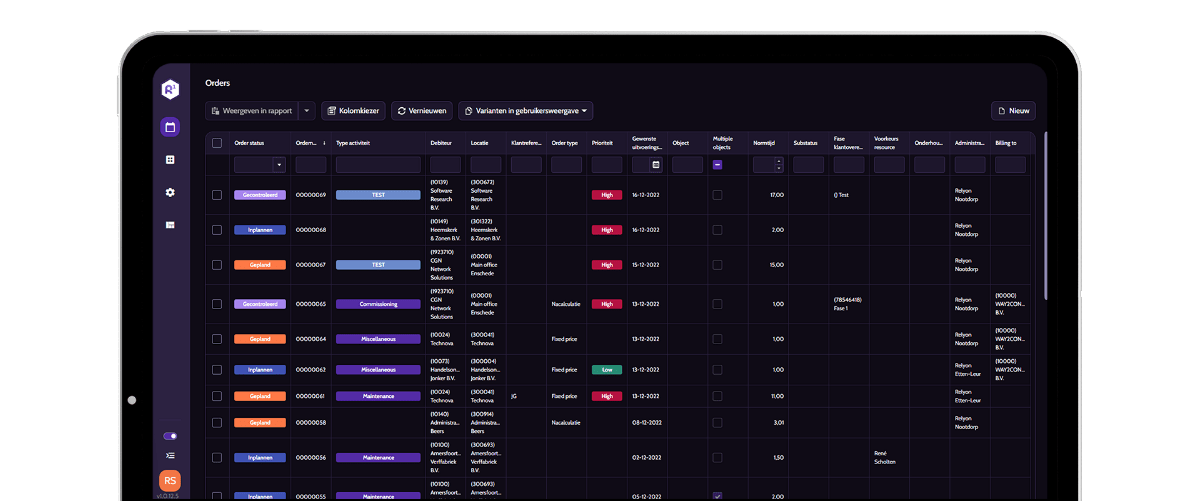

Until two years ago, a small number of employees still operated without the use of significant automation: the mechanics, who were on their way daily to replace and deliver tyres. “In those days we worked according to a book lying on the counter, used by everyone to write the assignments in”, Van der Veer recalls. “The mechanics were given job sheets, but frequently lost them. This led to more than occasional discussions with customers whether the work had been done or not.” Then AFAS sent an invitation to view a demonstration of the Relyon service management software. It was a remarkable day. “We instantly knew that Relyon could fill in the missing parts. Really, after only thirty minutes we were convinced. It was a matter of five specific questions. When Relyon adequately answered all of those questions, we knew we had found our partner.”

Van der Veer and Dorst were very enthusiastic. Dorst: “We said, now there is no way back. Our mechanics were thrown into the deep end from the start. It was rather daring, but it worked. We started, using the Relyon basis version and then, step by step, we adjusted the software to our demands. Within five or six weeks it seemed as if we had never operated in any other way. We had thought that the mechanics would experience difficulty, but it went rather smoothly. It was important that we involved the boys from the very beginning.” Van der Veer explains how they were persuaded. “The boys were in need of new telephones. Instead of using tablets, equipped with merely service management software, they started using a new smartphone. They did not need a private mobile anymore, as they were given a free call bundle. It turned out to be an excellent stimulus!”

A deal is a deal

Since Relyon integrated into AFAS, the service process is now automated from beginning to end. As invoicing and storage management is linked in AFAS, the administration is done in the blink of an eye. Van der Veer: “Whether the customer pays on account or cash, after the customer’s consent, the mechanic closes the order and sends the details through immediately. As soon as he leaves the customer’s premises, we can see which tasks have been carried out. Through AFAS, the invoice is submitted at once. That means we also get paid sooner.” Each and every day, the planners notice the flexibility of this solution. Dorst: “In the old days too, we would help our customers, doing rush jobs, but sometimes that resulted in internal chaos. Now, if there is a quick fix to be done, we can easily squeeze it in, and it won’t affect the rest of our work.” Van der Veer describes the consequences for the work climate: “It has taken away a lot of stress, both for us and the customer. There is now stability in our procedure. To the customer it is clear: a deal is a deal. And that is a commitment we fulfil every time.”

Anywhere in the business we can work faster and more efficiently with AFAS and Relyon.

Speaking of customers: they benefit most from the combination of AFAS and Relyon, both planners say, which they think is actually the most important thing. Van der Veer: “What distinguishes our company from others, is the service. Customers noticed it right away: we can now act very quickly. We used to always lose paperwork, particularly when it was needed most. But now misunderstandings are virtually impossible.” And internally? “In the workplace, it saves up to one FTE per year. We can work quicker and more efficiently at any place within the company, thanks to AFAS and Relyon. It is really amazing how much time is saved.” Dorst mentions another advantage: “Piet is getting older, but is now able to work from home more often. At the time we worked with work slips, they sometimes piled up so high that he needed to climb on something to be able to look through the window! Now he can work from a remote location. Also there are no more discussions about the distribution of the work. In fact, mechanics don’t even need to come by the office on Monday morning; their jobs are listed on their mobile phones. In the old days there used to be much confusion, now everything is crystal clear.”

Future plans

Bandenservice Zuid-West is also prepared for expansion to more branches. Van der Veer: “In 2012, we opened our branch in Noordwijkerhout, which we can support from here. Should we open more branches, then this solution is totally prepared for it.” In that regard, the tyre specialist has plenty of future plans for collaboration with AFAS and Relyon. Dorst: “We want to further develop our service by sending every next customer a text message about the arrival time. As such, he can prepare his machine on the premises and continue his own work. Practical for the customer and time saving for us.”

A next step is the processing of the mechanics’ working hours in the AFAS staff administration. Van der Veer: “We won’t use this to keep our mechanics alert as that would perhaps cause resentment. After all every person is different. What it will do, is make the relation between work and price transparent. We will notice sooner whether we charge too little or too much for certain activities, whereas for the customer it is clear how much time certain tasks will take.” Dorst: “The quality of our work is more important than our mechanics’ speed of working. This step, however, will contribute in finding the strong points of each mechanic. As a result, we will know which task to allocate to which mechanic, based on their skills.”